the quality of the geomembrane sheet

When purchasing geomembrane sheets for projects like landfills, ponds, or reservoirs, ensuring high quality is crucial for the longevity and effectiveness of the installation. the manufacturing and installation of geomembrane sheets demand unwavering commitment to quality control. By meticulously selecting materials, following best practices during manufacturing, and ensuring precise installation.Here are the key factors to consider when evaluating the quality of geomembrane sheets.

Material Composition

High-Density Polyethylene (HDPE) or HDPE geomembrane and Linear Low-Density Polyethylene (LLDPE) or LLDPE geomembrane are common choices. HDPE is known for its strength and chemical resistance, while LLDPE offers more flexibility. Check for UV stabilizers, antioxidants, and anti-aging additives that enhance durability.

Different geomembrane materials offer varying levels of durability, flexibility, and chemical resistance. Common materials include high-density polyethylene (HDPE), linear low-density polyethylene (LLDPE), polyvinyl chloride (PVC), and more. Consider the properties of each material and choose one that best suits your application, taking into account the substances it will be in contact with and the environmental conditions.

Thickness of the geomembrane sheet

Geomembrane thickness is crucial for its overall performance, including puncture resistance and durability. Thicker geomembranes generally offer better protection and longevity, but they may also be less flexible and more challenging to install. Choose a thickness that balances the need for strength and durability with ease of installation and project requirements.(1)

Typically varies between 0.5 mm to 3.0 mm.Thicker sheets generally offer better puncture resistance and durability but may be less flexible.

Physical Properties of the geomembrane sheet :

- Tensile Strength: Indicates the material’s ability to withstand pulling forces. High tensile strength is essential for withstanding mechanical stresses.

- Elongation: Measures the material’s ability to stretch before breaking. Higher elongation provides better adaptability to settling and ground movements.

- Puncture Resistance: Critical for preventing leaks and ensuring the integrity of the geomembrane.

- Tear Resistance: Important for withstanding forces that may cause tearing during installation or use.

Chemical Resistance

Evaluate the sheet’s resistance to chemicals present in the environment, such as acids, bases, and hydrocarbons. Ensure the material has been tested for chemical resistance relevant to your specific application.

Permeability

Impermeability: Low permeability is crucial for containment applications to prevent leakage of liquids or gases. Look for data on the sheet’s permeability to various substances.

Ultraviolet (UV) Resistance

UV resistance is essential for outdoor applications to prevent degradation from sunlight exposure.Additives: Check for the presence of UV inhibitors that protect against solar radiation.

Manufacturing Standards and Certifications

Ensure the product meets industry standards such as ASTM, GRI-GM13 (for HDPE), or ISO certifications.Look for manufacturers with quality control certifications like ISO 9001.

Verify that the geomembrane sheets have undergone rigorous factory testing for physical and chemical properties.Consider third-party certification or testing to confirm the quality.

Choosing a reliable and reputable geomembrane manufacturer and supplier, such as EPI, is critical. Ensure the manufacturer has a proven track record of providing high-quality products that meet industry standards and certifications. Additionally, consider their customer service, technical support, and warranty offerings to ensure a smooth and successful project.

Seam Strength

Check the quality and method of seam welding. Good seam strength is crucial for maintaining the integrity of large installations.Ensure that seams can withstand expected stresses and environmental conditions.

Surface Finish and Texture

Smooth geomembranes are easier to clean and weld, while textured sheets provide better frictional resistance for slope stability. Choose based on the specific requirements of your project.

Durability and Longevity

Look for information on the expected lifespan under specific conditions. Check if the manufacturer offers any warranties or guarantees on the product.

Cost vs. Quality

Balance cost with quality. While cheaper options may be tempting, they can lead to higher maintenance costs and potential failures. Investing in high-quality geomembrane sheets can reduce long-term risks and costs.

Quality control starts with material selection, with rigorous testing to ensure the chosen materials meet required specifications. Thickness, tensile strength, and elongation properties are scrutinized, and welding procedures are tested for seam integrity. These measures collectively contribute to the overall robustness of the geomembrane.(2)

Supplier Reputation

Look for reviews or case studies from previous users to gauge performance.Choose reputable suppliers who offer technical support and after-sales service.

Environmental Considerations

Consider the environmental impact of the geomembrane, including the material’s recyclability and any certifications for environmental safety. Ensure compliance with environmental regulations and standards.

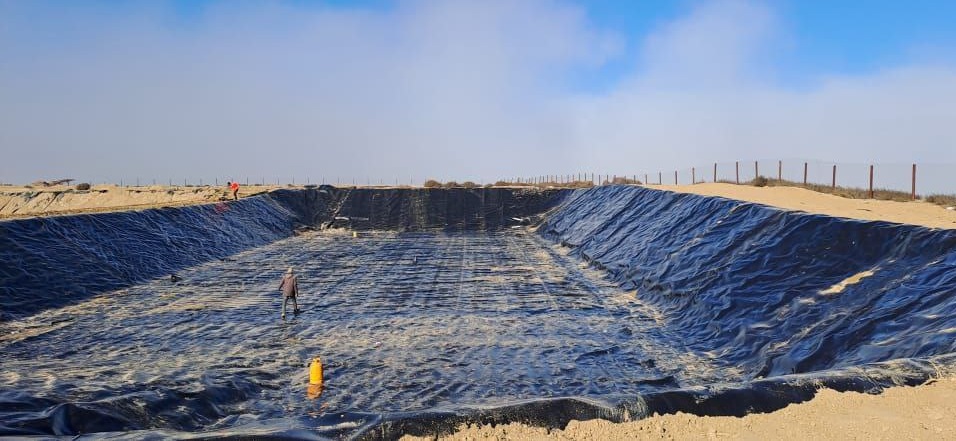

Installation Procedures

Proper installation is as crucial as quality manufacturing. Site preparation, including thorough inspection and soil testing, sets the foundation for a successful installation. Employing skilled labor familiar with industry standards is essential to avoid common pitfalls during the installation process.

Summary the quality of the geomembrane sheet before buying

Evaluating the quality of geomembrane sheets involves a comprehensive assessment of material properties, performance characteristics, and compliance with standards. By focusing on these factors, you can ensure that the chosen geomembrane will meet the demands of your project, providing reliable performance and long-term durability.

comments: 0 comment